The Nuclear AMRC has helped hundreds of companies to achieve their goals through manufacturing innovation and supplier development.

We have worked with businesses of all sizes to help them become more competitive, and delivered real business benefits. We have helped companies win billions of pounds of new business, and create or safeguard thousands of jobs.

You can discover some of our recent success stories below. Click on the title or image to open each case study as a two-page pdf.

For the latest news on how we’re helping UK manufacturers win work in civil nuclear and other innovative energy sectors, see our quarterly newsletter.

Waste container prototyping for Capsa Solutions

Waste container prototyping for Capsa Solutions Affirming the promise of automated weld inspection

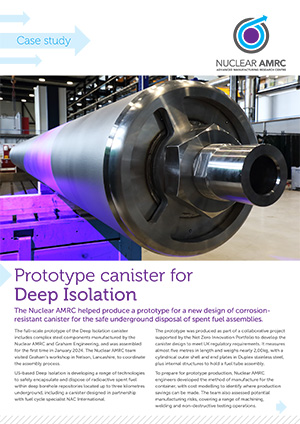

Affirming the promise of automated weld inspection  Prototype canister for Deep Isolation

Prototype canister for Deep Isolation Dynamic Aerospace Fabrications moves to diversify in nuclear

Dynamic Aerospace Fabrications moves to diversify in nuclear

Hyde Group Nuclear puts focus on quality

Hyde Group Nuclear puts focus on quality